- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Як впливає 4-в-1 ручна лазерна зварювальна машина в очисних зварювальних швах?

2025-03-31

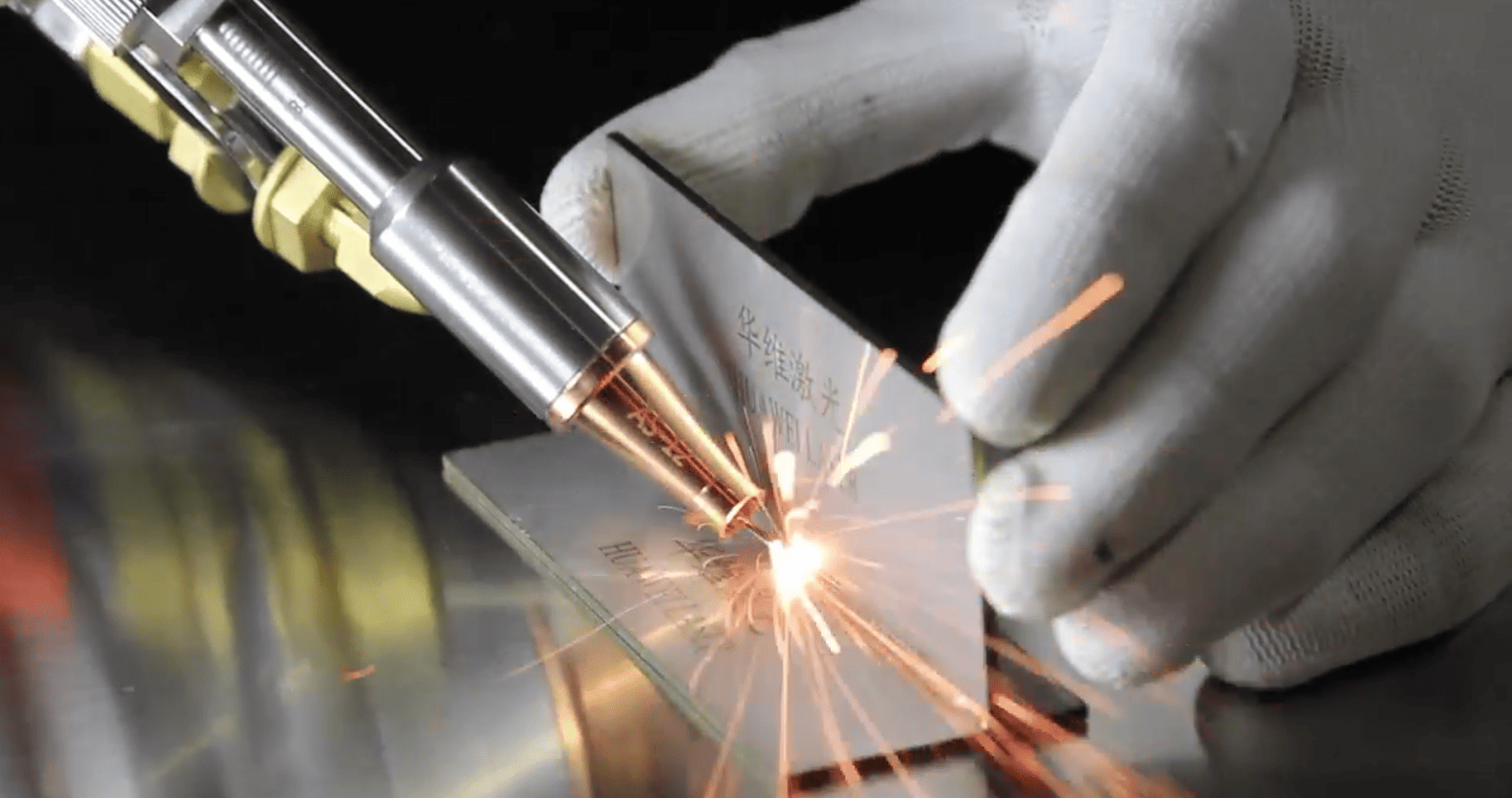

The 4-in-1 handheld laser welding machine launched by Huawei Laser integrates four functions: laser welding, laser cutting, laser cleaning, and welding seam cleaning, providing a one-stop high-efficiency solution for the metal processing industry. While its primary function is laser welding, achieving high-efficiency and high-precision welding, how effective is this 4-in-1 handheld laser welding machine in cleaning welding seams?、

After welding, a layer of black oxide typically forms on the surface. In traditional welding processes, cleaning the welding seam often requires the use of chemical agents or mechanical grinding, which is not only time-consuming and labor-intensive but can also affect material performance. Laser cleaning technology, however, can quickly remove this black oxide by scanning the welded surface, restoring the base material to its original color.

Advantages

Efficient Removal of Impurities: The laser welding machine can instantly vaporize surface contaminants during the welding process, reducing welding seam defects and improving yield.

Reduced Secondary Processing: No additional chemical cleaning or mechanical grinding is required, lowering production costs and reducing environmental pollution.

Precise Control of Cleaning Range: The laser beam energy can be finely adjusted, ensuring no damage to the base material, making it suitable for precision manufacturing industries with high standards.

Improved Welding Quality: Reduces common welding defects such as porosity and cracks, enhancing the strength and durability of the welding seam.

Suitable for Multi-Layer and Multi-Pass Welds: In multi-layer and multi-pass welding situations, laser cleaning efficiently removes interlayer impurities, ensuring welding quality and improving the sealing of the welding seam.

Pre-Treatment Before Welding: Laser cleaning can also be used for pre-treatment of metal surfaces before welding, removing debris and reducing common welding defects such as porosity, slag inclusions, and incomplete fusion.